Barcode Scanner Stock for OpenERP 6.1

Àngel Àlvarez Serra Jul 20, 2012

Today we present our module nan-stock-scanner for OpenERP 6.1

Installation

You can download the module in the project page https://github.com/angelnan/nan_openerp_modules.git and clone it using the version control system git clone https://github.com/angelnan/nan_openerp_modules.git or download the latest version as a zipped file in https://github.com/angelnan/nan_openerp_modules/zipball/6.1

Keep in mind that you can find more modules in the repository.

Once downloaded:

- Unzip if necessary, and copy or move the usual route of the ERP modules.

- Reboot the OpenERP server.

- Log in using the client.

- Update the list of modules (Administration/Modules).

- Locate and install the module nan_stock_scanner.

Let's go how it works

User Guide

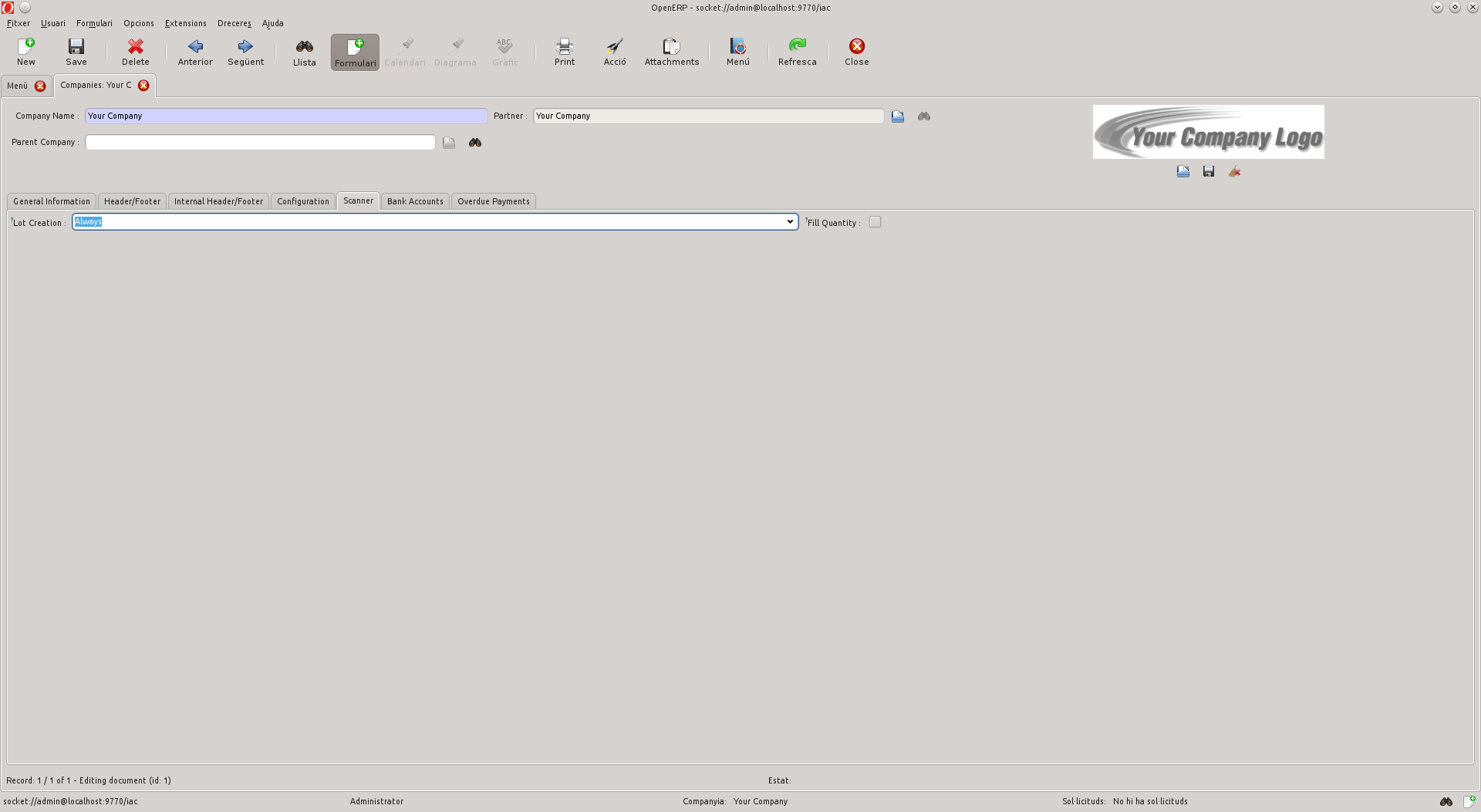

Configuration

We have two options, first related to production lots of the input pickings:

- Never: Don't create production lots.

- Always: Create a new production lot in each input.

- Assing by supplier reference: Search a production lot with the supplier reference and create a new one if there is no match.

The second reports the scanned quantity:

- Add a unit in each scanning (default).

- Fill with the expected quantity of the associated movement.

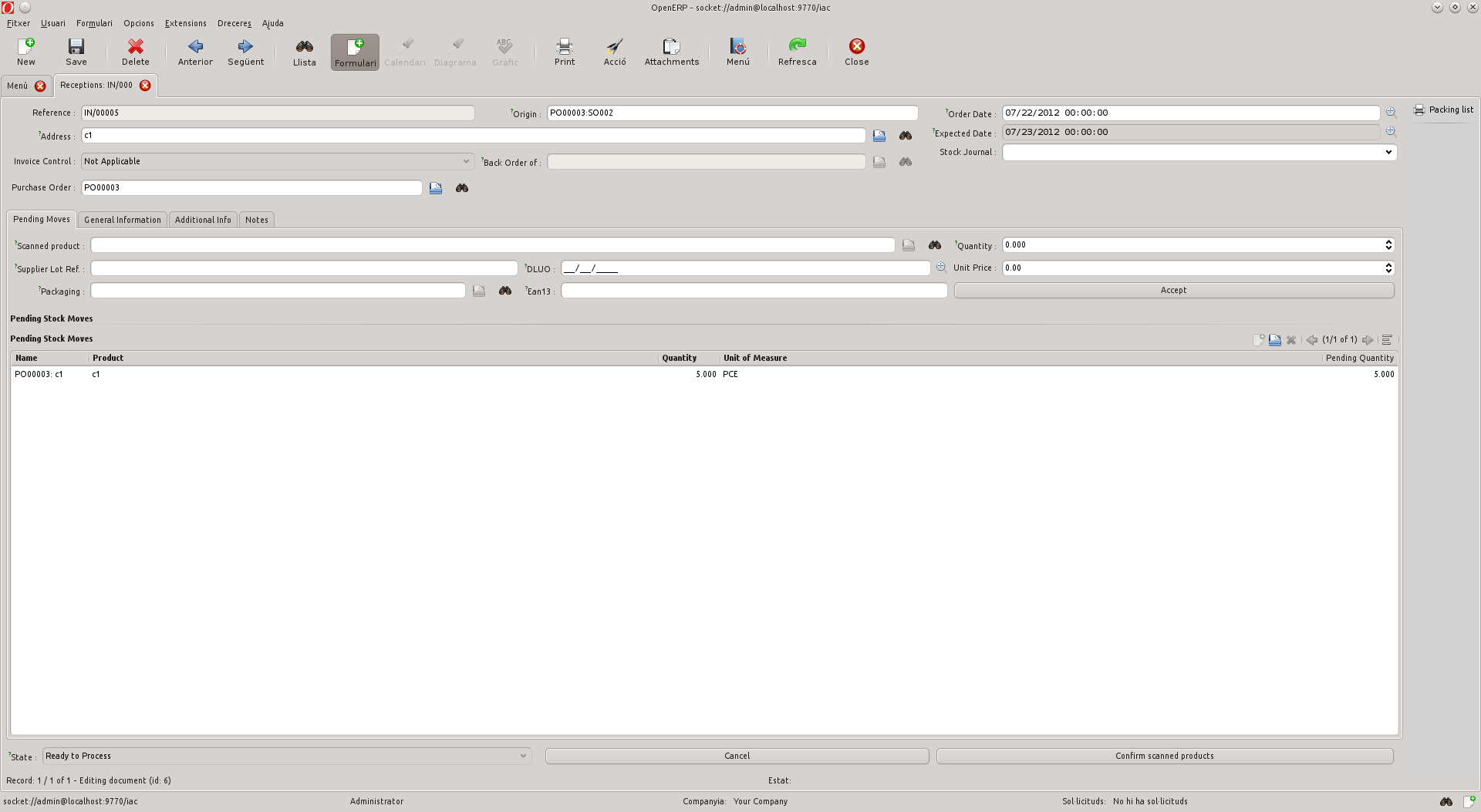

Input Pickings

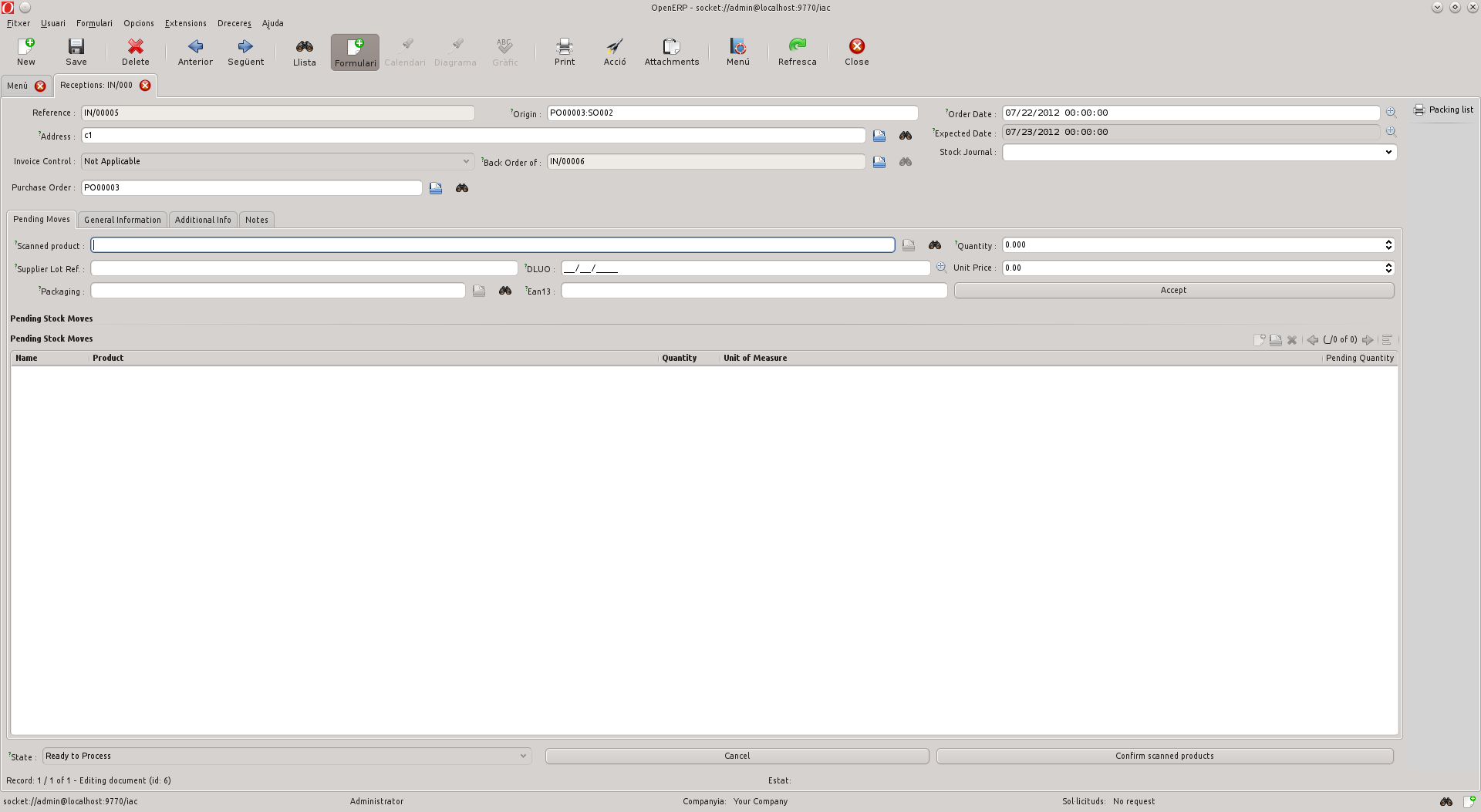

In any input picking, and the rest of pickings, you could find a new tab: pending moves . It indicate the quantity of products that remain to scan and information of one: quantity, the supplier reference, expiration date, purchase price, packing and EAN code.

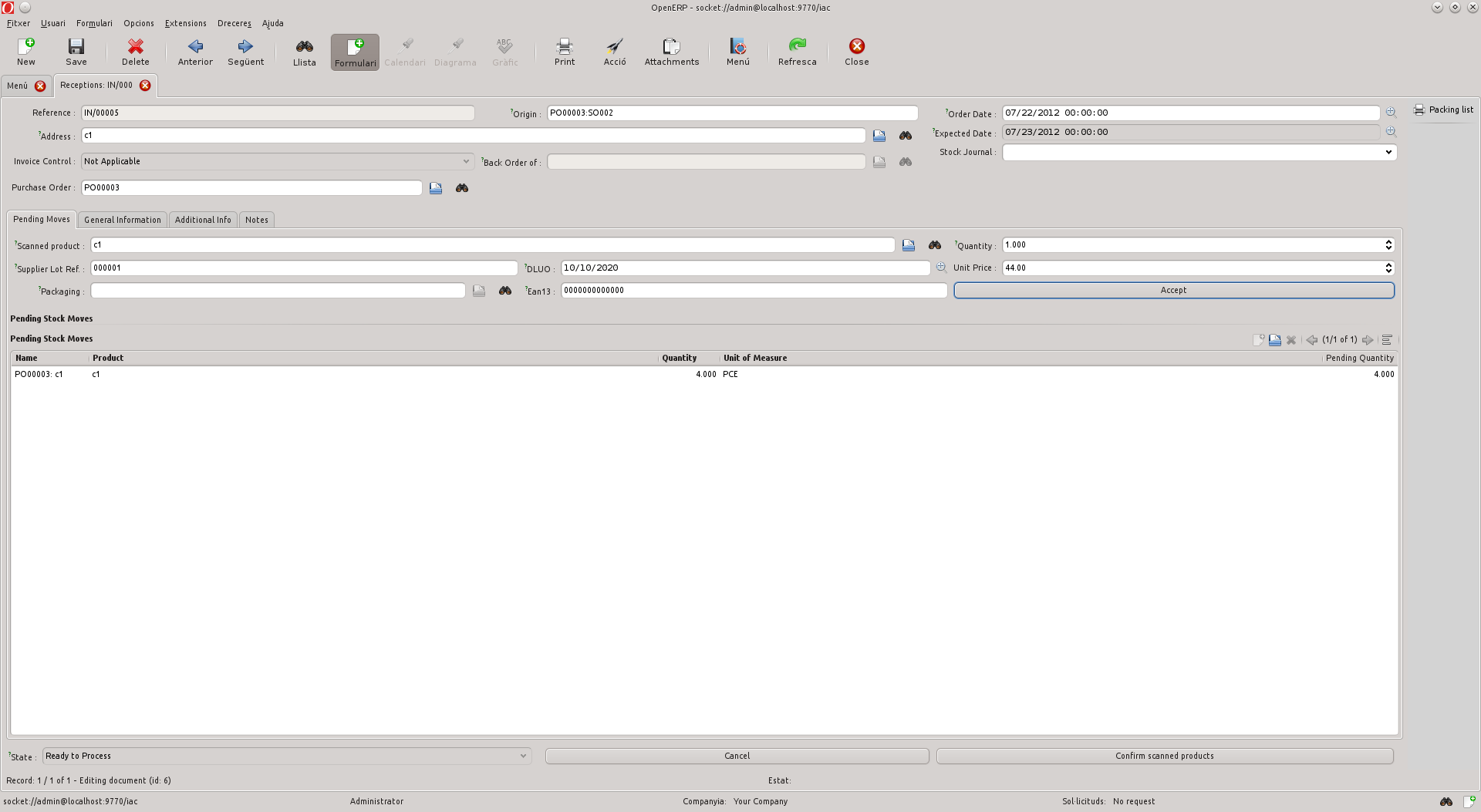

The scanning process automatically fills the fields of quantity and unit price with purchase information associated (depending on configuration). You could manually complete the fields of expiration date and the supplier reference to create the lot with the data required.

The new tab also facilitates EAN 13 code assignment to the product if there are none associated. During the scanning process you could complete manually the field with the EAN 13 code that is automatically stored in the product on the validation.

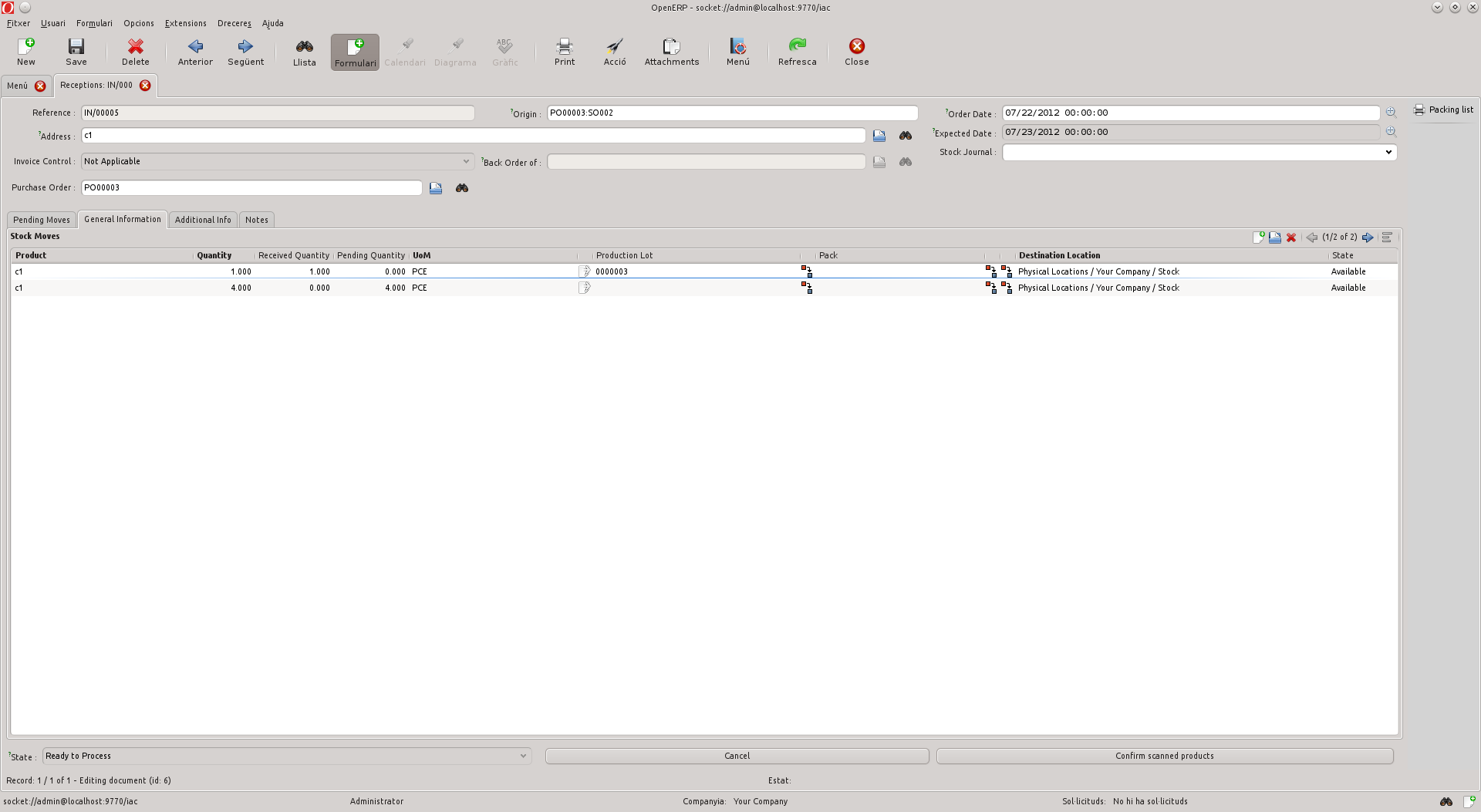

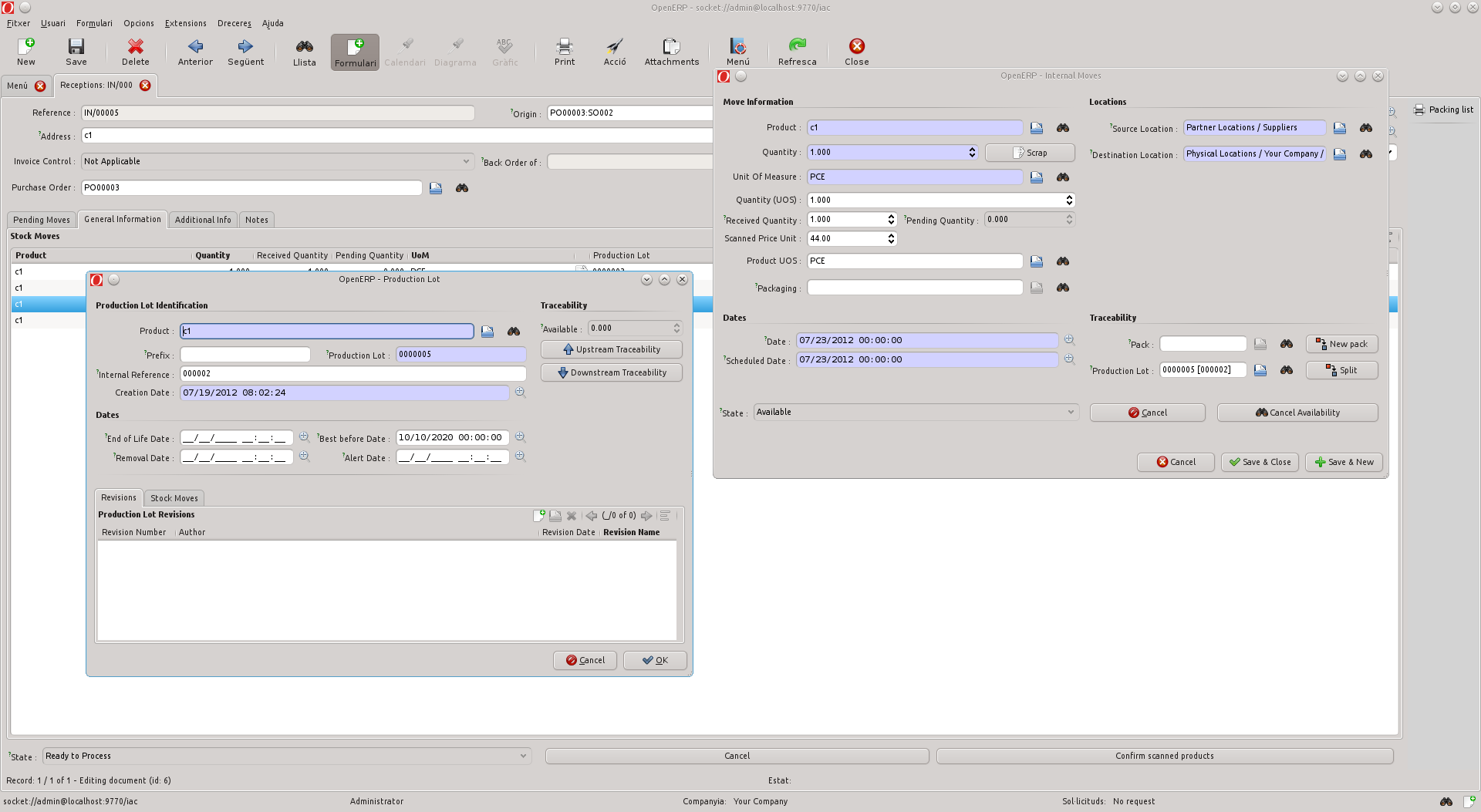

On this screen you can see how the products have been divided, a unit has been scanned with with its production lot and the rest is pending.

In the next shoot you could see the different tabs with the updated inforamtion of the scanning process.

Finally the screen once completed the scan of the input picking.

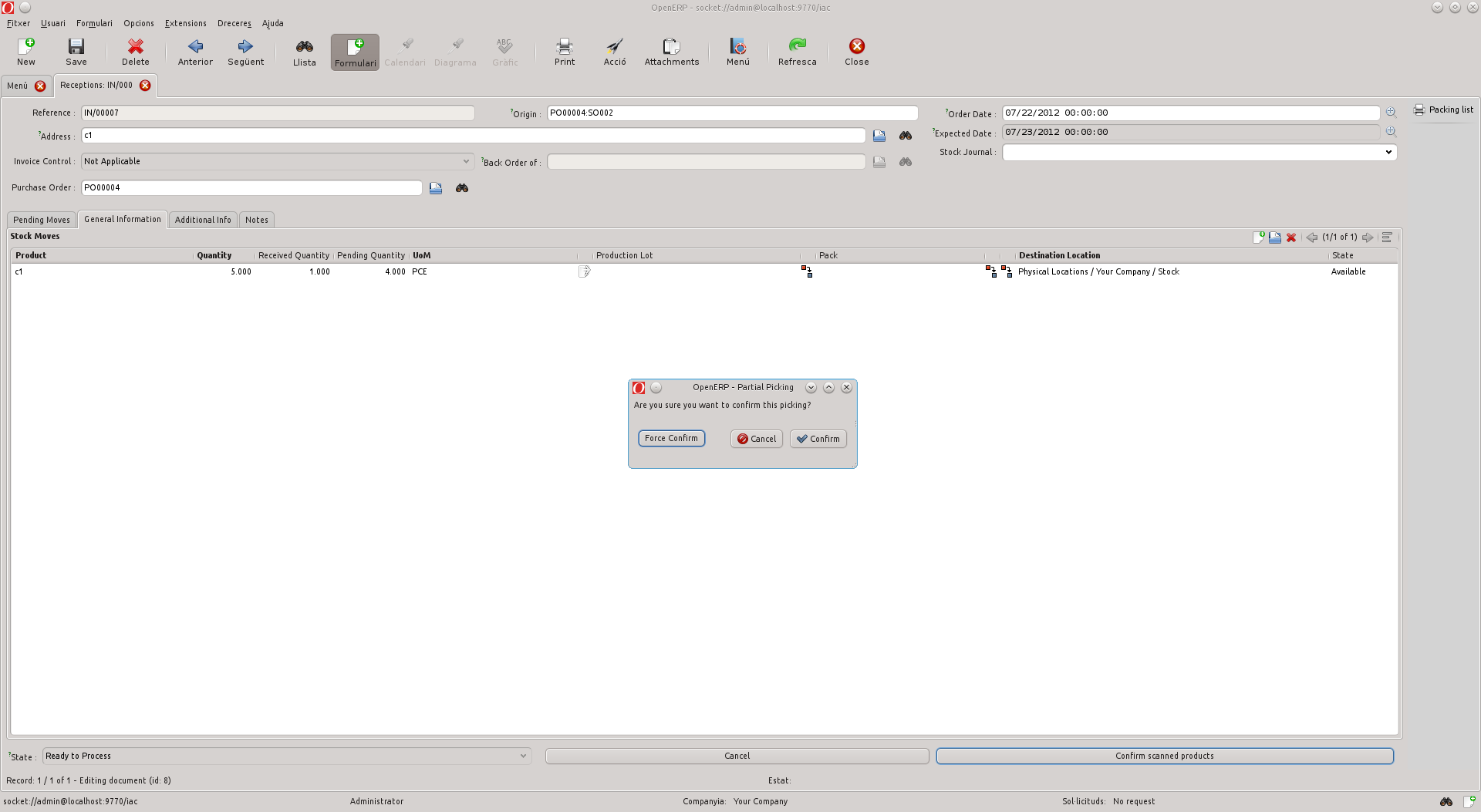

You can also create partial picking with a ingle click on the Confirm scanned products. In this case appears a small screen where you could:

- Confirm: Create a partial picking if necessary comparing the expeted and the received quantity.

- Cancel: Abort confirmation.

- Force confirm: We assume that we have received all the goods and confirm the delivery note.

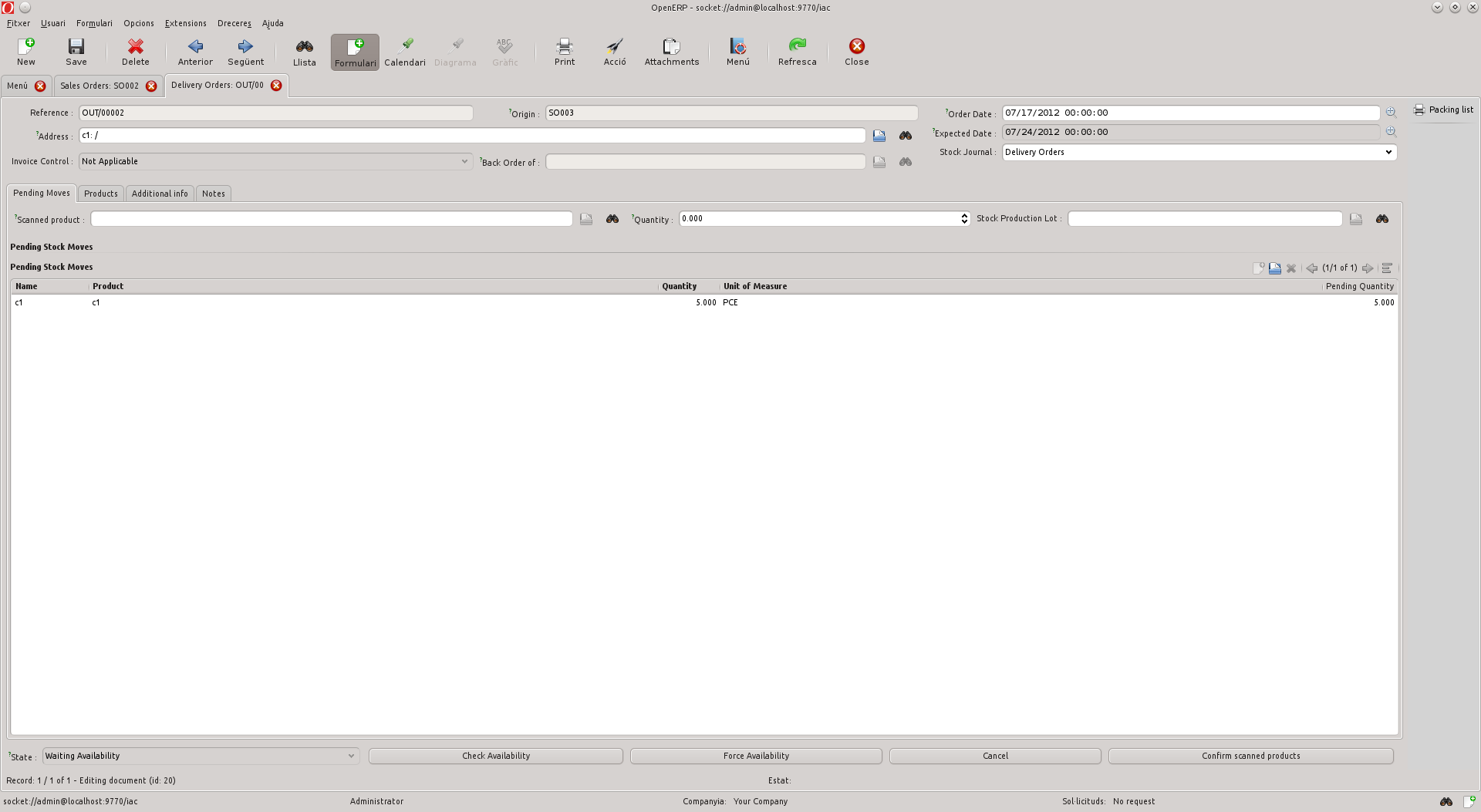

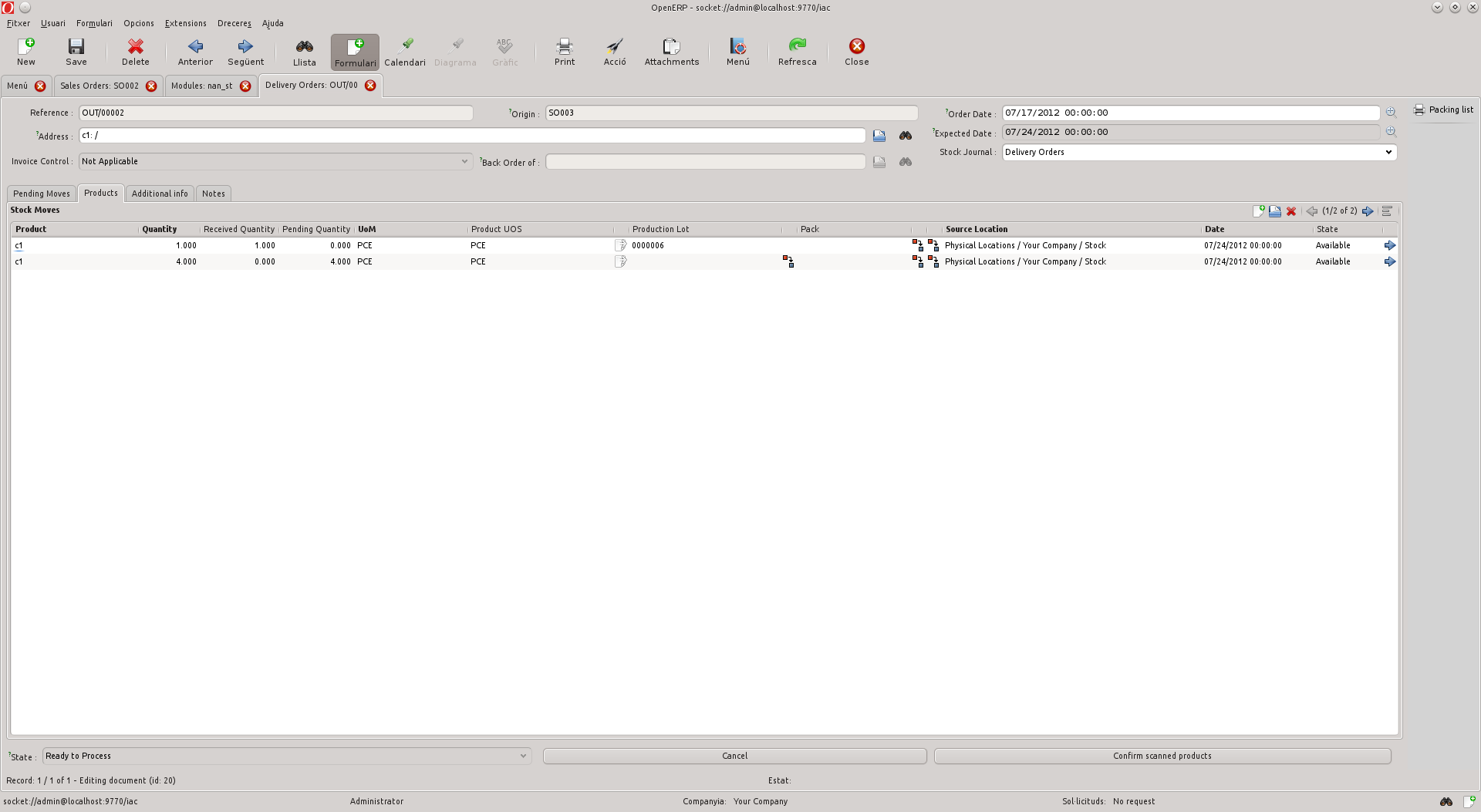

Output and Internal Picking The output and the internal picking are simpler as there are only information about product, quantity and production lot to scan.

Just as in any picking, the products are separated by the production lot.

The rest of the process is exactly the same as the described in tne Input Picking, with full or partial picking depending on the differences between the expected and real quantities moved.